Tagged: @falak

-

Task 1 (Process) : Cement -making process

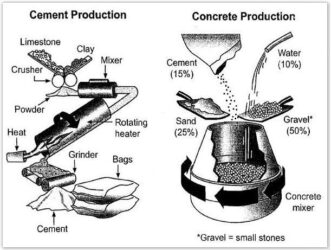

Posted by Falak on December 25, 2021 at 4:13 PMThe diagram below shows the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes.

Summarise the information by selecting and reporting the main features and make comparisons where relevant.

» You should write at least 150 words.

Falak replied 3 years, 4 months ago 6 Members · 8 Replies -

8 Replies

-

Unknown Member

Deleted UserDecember 26, 2021 at 6:12 PMThe two given diagrams illustrate the necessary steps and materials used for both cement and concrete production processes .

Overall, it is clearly seen that , the cement production involves some complex stages , while concrete production is done by using just cement , water , sand and gravel in concrete mixer .

The first diagram shows that , limestone and clay are crushed into a powder form, after that, the powder goes into a mixer . Then it passed via rotating heater with the supporting fire in the end of mechanism . After heating step, the powder turns into a paste which is passed to grinder machine to create the cement . Finally , this cement becomes ready to packed in bags.

The second diagram depicts the process where all the main components such as 15% of cement , 10% of water , 25% of sand and 50% of gravel are mixed together in a huge machine to create concrete .

-

The first diagram shows that , limestone and clay are crushed into a powder form (using crusher)

Then it passed (passes) via

rotating heater with the supporting fire (at the other end of the tube) in the end of mechanism

The second diagram depicts the process where all the main components such as 15% of cement , 10% of water , 25% of sand and 50% of gravel are mixed together in a huge machine to create concrete . (you could mention the specification of gravel as mentioned in the diagram )

Feedback : Include all steps and specifications(if possible) , to reach required word limit

Band: 2/3

-

-

The illustration shown represents the process of converting raw materials into cement and operation to obtain concrete used for construction activities.

Overall, the procedure of manufacturing cement, involves a cycle of crushing mixing and grinding of raw materials while concrete used as building essentials is collected by mixing cement along with other natural resources in accurate proportions.

In the first diagram, the crushed mixture of limestone and clay, received from crusher is sent into the mixer where powder materials are mixed precisely. The extracted elements are then taken through rotating heater where heat is continuously applied on the rotating shaft. The eliminated products are then grinded perfectly on grinder to release cement collected in the bags.

The second diagram depicts event involved in extracting concrete used for commercial purposes. The process includes utilization of cement withdrawn from first batch of processes. The mixture containing 15% cement alongside 10% water, 25% sand and 50% gravel is sent through a rotating instrument called concrete mixer to withdraw concrete to be used for building chores.

Word Count : 172

-

cycle of crushing(,) mixing and grinding

where powder (powdered) materials are mixed precisely.

well – written ,with good overall progression and apt use of lexical resources.

keep writing!!!

Band: 2.5/3

-

-

The above diagram explains the process of cement and concrete production. the illustration on the left show how cement is made from limestone and clay. while, the illustration on the right, shows how cement, sand, water and gravel are used to prepare concrete.

Overall, the interpretation of the diagram shows that limestone and clay go through a complete industrial process to become cement. concrete is mixture of multiple materials which include cement, water, sand and gravel. the materials are mixed thoroughly in a concrete mixer.

Cement production starts with crushing of limestone and clay and that powder is sent to the mixer. later it is heated in the rotating heater. finally, the powder is grinded and packed into the bags. the concrete mixer is responsible for preparation of concrete.

However, concrete needs cement for its preparation. while gravel is 50 percent of the mixture, cement (15%), sand (25%) and water (10%) are used in less proportions. both processes are similar, but the only difference is cement production is in dry form and concrete production is in wet form.

-

These pictures illustrate how cement is produced, and how concrete is made. Overall, the process of making cement uses some tools and consists several stages, as the production of concrete requires only a mixer.

At the first stage, limestone and clay are crushed through crusher machine and turned into powder. These powders are mixed together by mixer and sent into rotating heater which works with heat. After that these materials are gone into grinder and changed to cement which are packed in bags.

Furthermore, in the concrete production, there are four main elements including: cement, water, sand and gravel. Each of them has a certain percentage to produce concrete with 15 percent cement, 10 percent water and sand and gravel percentages are 25% and 50% respectively. These materials are mixed together in a big concrete mixer which leads to producing concrete for building aims.

In conclusion, it is clear from the diagrams that there are four important stages in cement production while concrete production has only one stage. More over, cement is produced by mixing two elements while concrete is produced by mixing four elements.

-

The given diagrams illustrate the process of converting the different materials into cement and the preparation of concrete using cement and water.

Overall, the procedure involved for creation of cement consists of cycle of crushing, mixing and grinding of raw materials respectively, whereas the concrete used for construction undergoes phase of mixing the cement with other materials in definite proportions.

In first diagram, materials like limestone and clay are crushed together through crusher; moreover, the crushed materials are passed to the mixer where powdered items are mixed. The extracted elements are taken to a rotating heater where they are continuously heated by a rotating shaft. In the end, the excreted products are grinded perfectly on grinder along with their proper packaging in bags.

The second diagram demonstrates the stage of extracting concrete used for multiple purposes. The process includes usage of cement acquired from the first phase of process. The mixture that contains 15% cement, 10% water, 25% sand and 50% gravel is passed through a rotating instrument called as concrete mixer to acquire the final product that is concrete.

-

e procedure involved (involves)

for creation of cement (“for” is not required)

er; moreover, (furthermore)

keep writing!!

-

Log in to reply.